Position: Home > New

Facing the increasingly stringent fuel consumption emission regulations, automobile energy saving and emission reduction has become the top priority of the car enterprises and related enterprises. In the energy-saving emission reduction technology roadmap, the lightweight of the car has become a must. The total mass of vehicle fuel consumption mainly depends on the displacement of the engine and the car in the car, keep the overall quality, performance and cost optimization under the premise of constant or even reduce the car's own weight, can increase the output power, reduce the noise and enhance the maneuverability, reliability, improve vehicle speed, reduce fuel consumption, reduce emissions, improve safety. The most effective ways to achieve lightweight include the use of lightweight materials and the manufacture of automotive components by optimizing structures and processes.

With the development of automobile lightweight, the technology of automobile die casting, automobile casting structure development, design and production technology has been greatly breakthrough. In July 19-21, CHINA 2017 DIECASTING twelfth Chinese Die Casting Exhibition, more than 300 domestic and foreign suppliers gathered in a die casting industry chain, technology and process of the latest show, and to bring the new product appearance, show their own in automotive lightweight has strong comprehensive strength. It is worth noting that, in this exhibition, a large number of local high-end and high-quality casting enterprises have emerged, highlighting the level of China's casting technology has been close to the world's advanced ranks.

Ningbo Beilun match Vinda Machinery Co. Ltd. (hereinafter referred to as the "Vinda game"), with vacuum die-casting technology, automatic trimming precision die technology fun lightweight vehicles, in addition to the car, the Mexico Leon plant will be completed this year and put into operation, will not only help to open up overseas markets, will also enhance the Vinda game domestic competitiveness.

In the field of die casting exhibition site, CITIC Dicastal Limited by Share Ltd display hub, cylinder head cover, Aluminum Alloy casting, its excellent performance won the customers and the industry recognition.

The aluminium alloy auto parts products displayed by Suzhou Cheng Cheng Precision Casting Co., Ltd. have reached or been close to the advanced level in the aspects of design, manufacture, technology, equipment and quality.

In addition, deshengmei Automobile Parts Co. Ltd and other famous enterprises have exhibited casting products with high technical content.

Low pressure casting machine, which is specially designed for the casting of aluminum alloy wheel, is a LA-D8090 low pressure casting machine, which has the characteristics of automatic demoulding, automatic fetching and high production efficiency.

The face of the grand industry event, well-known foreign companies certainly will not miss the opportunity, from Germany, Japan, Italy, Britain, the United States, France, South Korea, Switzerland, Sweden, Denmark, Austria, India, Spain, Thailand, Iran, Czech and other countries of the enterprise also brought new technologies and achievements.

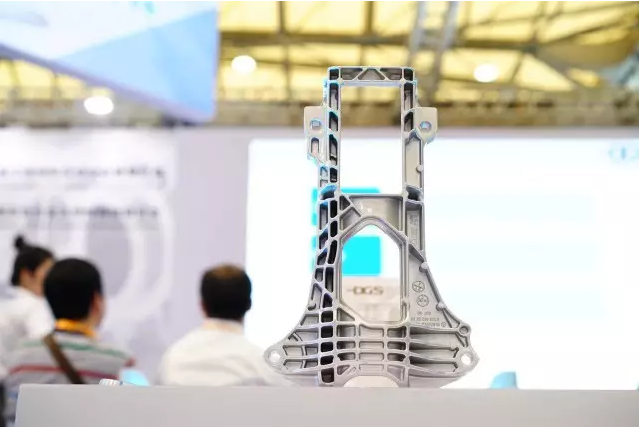

In the die casting exhibition, Switzerland DGS group in Chinese wholly owned subsidiary of Guangzhou tokushi metal products Co. Ltd. (hereinafter referred to as "Guangzhou De Zhi") as the first production car with one of the few parts of the structure of die casting company. The exhibition of Guangzhou volunteers to die casting automobile lightweight theme debut showcase the latest structural products from Switzerland, Guangzhou factory production of auto parts, used for high quality Aluminum Alloy, magnesium alloy and magnesium alloy die casting, applications cover body, front end module, steering system, instrument panel assembly, and brake gear system.

Italy Peres / Gauss automation Limited by Share Ltd is a comprehensive international supplier of casting equipment and automation solutions for the nonferrous casting enterprises, the application of manufacturing equipment and automation unit production Aluminum Alloy front shock tower, magnesium alloy castings such as the trunk.

Kurt electrical equipment (Shanghai) Co., Ltd is a full set of equipment and solutions provider casting low pressure casting industry renowned, it provides intelligent production line for low pressure casting, Home Furnishing, 3C lighting, in many industries, especially in the automotive industry, to provide equipment support for product quality of aluminum and magnesium alloy castings. The manufacturing of low pressure casting equipment, the first mock exam can produce two pieces of engine block, compared with the general yield of double low pressure casting machine.

The current situation of the industry, casting industry automobile market opportunities and technological progress based on the expanding has achieved good results, but we should also recognize that the global automotive aluminum casting steady growth, but growth slowed down, China die-casting industry enterprises, but the scale is uneven; China die casting technology progress is obvious, but the lack of lead." Professor Wu Guohua of Shanghai Jiao Tong University said.

From the current market, the die casting technology began to migrate from luxury cars to the car terminal, the required number of die casting structure will increase significantly; a small part of high pressure structure is still only Zhanya casting market, but the growth rate will accelerate, structure of die-casting unit in the construction of the increase; with the enterprise technology research and development and the breakthrough, can undertake structure of die-casting manufacturers will increase, so the structure of die casting parts still have competition.